Silk has set the standard in luxury fabrics for several millennia. The origins of silk date back to Ancient China. Legend has it that a Chinese princess was sipping tea in her garden when a cocoon fell into her cup, and the hot tea loosened the long strand of silk. Ancient literature, however, attributes the popularization of silk to the Chinese Empress Si-Ling, to around 2600 B.C. Called the Goddess of the Silkworm, Si-Ling apparently raised silkworms and designed a loom for making silk fabrics.

The Chinese used silk fabrics for arts and decorations as well as for clothing. Silk became an integral part of the Chinese economy and an important means of exchange for trading with neighboring countries. Caravans traded the prized silk fabrics along the famed Silk Road into the Near East. By the fourth century B.C. , Alexander the Great is said to have introduced silk to Europe. The popularity of silk was influenced by Christian prelates who donned the rich fabrics and adorned their altars with them. Gradually the nobility began to have their own clothing fashioned from silk fabrics as well.

Initially, the Chinese were highly protective of their secret to making silk. Indeed, the reigning powers decreed death by torture to anyone who divulged the secret of the silk-worm. Eventually, the mystery of the silk-making process was smuggled into neighboring regions, reaching Japan about A.D. 300 and India around A.D. 400. By the eighth century, Spain began producing silk, and 400 years later Italy became quite successful at making silk, with several towns giving their names to particular types of silk.

The first country to apply scientific techniques to raising silkworms was Japan, which produces some of the world’s finest silk fabrics. Other countries that also produce quality silks are China, Italy, India, Spain, and France. China was the largest exporter of raw silk in the early 1990s, accounting for about 85% of the world’s raw silk, worth about $800 million. Exports of China’s finished silk products were about half of the world’s total at about $3 billion.

Silk is highly valued because it possesses many excellent properties. Not only does it look lustrous and feel luxurious, but it is also lightweight, resilient, and extremely strong—one filament of silk is stronger then a comparable filament of steel! Although fabric manufacturers have created less costly alternatives to silk, such as nylonand polyester, silk is still in a class by itself.

Raw Material

The secret to silk production is the tiny creature known as the silkworm, which is the caterpillar of the silk moth Bombyx mori. It feeds solely on the leaves of mulberry trees. Only one other species of moth, the Antheraea mylitta, also produces silk fiber. This is a wild creature, and its silk filament is about three times heavier than that of the cultivated silkworm. Its coarser fiber is called tussah.

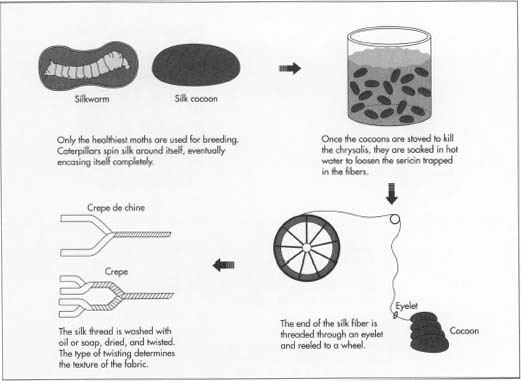

The life cycle of the Bombyx mori begins with eggs laid by the adult moth. The larvae emerge from the eggs and feed on mulberry leaves. In the larval stage, the Bombyx is the caterpillar known as the silkworm. The silkworm spins a protective cocoon around itself so it can safely transform into a

chrysalis. In nature, the chrysalis breaks through the cocoon and emerges as a moth. The moths mate and the female lays 300 to 400 eggs. A few days after emerging from the cocoon, the moths die and the life cycle continues.

The cultivation of silkworms for the purpose of producing silk is called sericulture. Over the centuries, sericulture has been developed and refined to a precise science. Sericulture involves raising healthy eggs through the chrysalis stage when the worm is encased in its silky cocoon. The chrysalis inside is destroyed before it can break out of the cocoon so that the precious silk filament remains intact. The healthiest moths are selected for breeding, and they are allowed to reach maturity, mate, and produce more eggs.

Generally, one cocoon produces between 1,000 and 2,000 feet of silk filament, made essentially of two elements. The fiber, called fibroin, makes up between 75 and 90%, and sericin, the gum secreted by the caterpillar to glue the fiber into a cocoon, comprises about 10-25% of silk. Other elements include fats, salts, and wax. To make one yard of silk material, about 3,000 cocoons are used.